# Common Challenges in Servo Motor Inventory and How to Overcome Them

Servo motors, particularly brushless motors, are integral components in various industries, including robotics, automation, aerospace, and manufacturing. Their ability to provide precise control of angular position, velocity, and acceleration has made them a preferred choice for applications requiring high performance and reliability. However, managing servo motor inventory poses several challenges that can hinder operational efficiency and increase costs. This article explores common challenges in servo motor inventory management and offers strategies to overcome them.

## Understanding Servo Motors and Their Importance

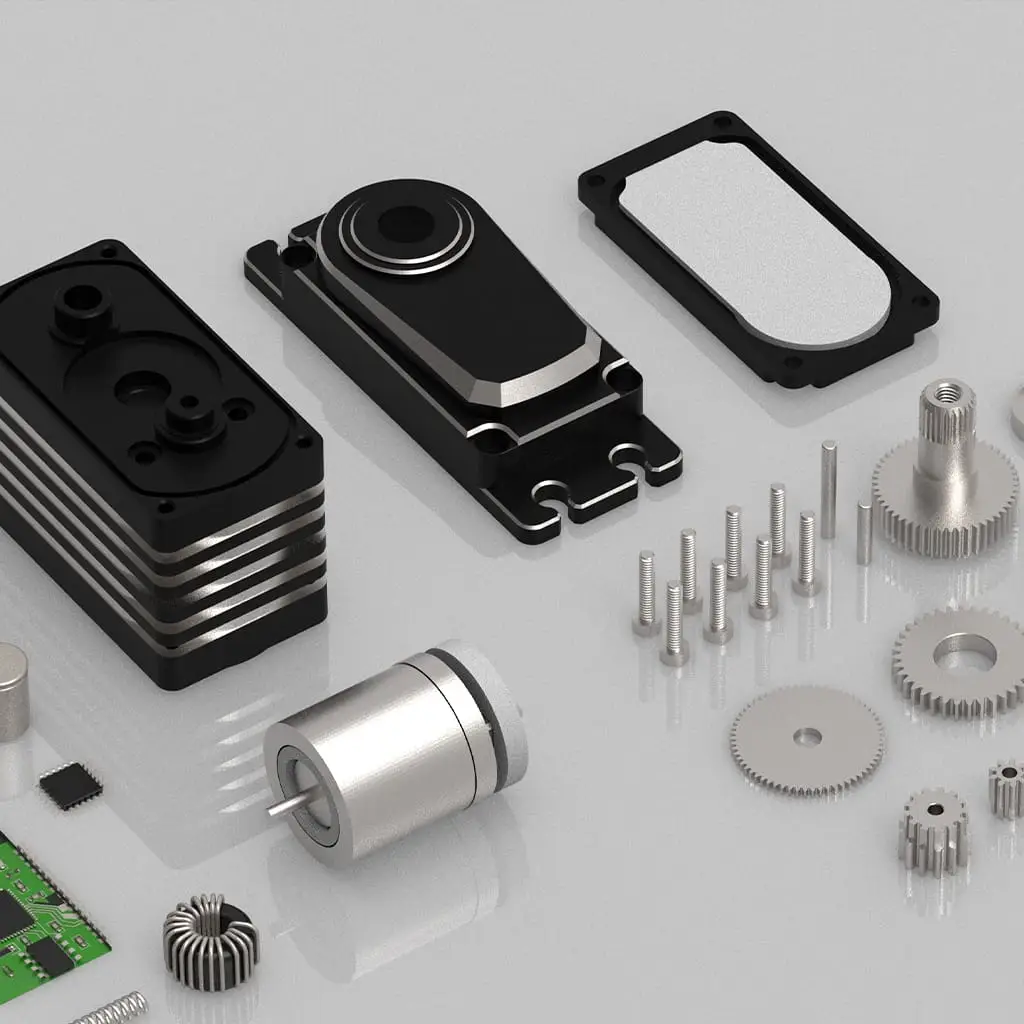

Before diving into the challenges, it’s important to understand what servo motors are and why they are critical in modern technology. Servo motors are electric motors that are designed to precisely control motion. They consist of a motor coupled to a sensor for position feedback, often making them more efficient and effective than traditional motors.

Brushless DC motors (BLDC) are a type of servo motor gaining popularity due to their high efficiency, low maintenance, and longer lifespan compared to brushed motors. These characteristics make them ideal for applications where reliability and performance are paramount.

## Common Challenges in Servo Motor Inventory Management

### 1. Demand Forecasting

Accurate demand forecasting is crucial for maintaining optimal inventory levels. However, predicting the demand for servo motors can be challenging due to fluctuating market conditions and varying project timelines. Industries relying on these motors may experience seasonal spikes in demand or sudden shifts due to technological advancements, making it difficult to maintain an accurate inventory.

### 2. Diverse Product Range

Servo motors come in various sizes, specifications, and functionalities, often tailored to specific applications. This diversity can complicate inventory management, as companies must stock a wide range of products to meet different customer needs. Balancing a diverse inventory while minimizing excess stock can be a daunting task.

### 3. Supplier Reliability

Reliability of suppliers plays a critical role in servo motor inventory management. Disruptions in the supply chain, such as delays in delivery or quality issues, can lead to production halts. Companies must ensure that their suppliers can consistently provide quality components in a timely manner.

### 4. Technological Advancements

The rapid pace of technological change in the servo motor industry means that new models and features are constantly emerging. Keeping up with these advancements can lead to an increased risk of obsolescence for existing inventory. As older models become outdated, companies may find themselves holding inventory that is no longer in demand.

### 5. Cost Management

Servo motors, particularly high-performance brushless models, can be expensive. Managing the costs associated with acquiring and maintaining this inventory is essential for profitability. Companies must balance purchasing enough units to meet demand while avoiding overstocking, which ties up capital and increases storage costs.

### 6. Space Constraints

Physical space for storing servo motors can be limited, especially in smaller facilities. Efficiently utilizing available storage space while ensuring easy access to inventory can present logistical challenges. Inadequate storage solutions can lead to disorganization and difficulty in tracking inventory levels.

### 7. Data Management

Tracking inventory levels, order statuses, and supplier information requires effective data management systems. Many companies struggle with outdated or inefficient inventory management systems that do not provide real-time insights. Without accurate data, decision-making becomes difficult, leading to potential stockouts or overstock situations.

## Strategies to Overcome Inventory Challenges

### 1. Implement Advanced Demand Forecasting Techniques

To improve demand forecasting accuracy, companies should consider utilizing advanced analytics and machine learning algorithms. These tools can analyze historical demand data, market trends, and external factors to generate more precise forecasts. Collaborating closely with sales teams and customers can also provide valuable insights into expected demand.

### 2. Optimize Inventory Diversification

While it is essential to carry a diverse range of servo motors, companies should focus on optimizing their inventory mix. Conducting a thorough analysis of past sales data can help identify which products are most in demand and which are less frequently sold. This allows businesses to tailor their inventory to meet customer needs while minimizing excess stock.

### 3. Strengthen Supplier Relationships

Building strong relationships with reliable suppliers is key to ensuring a consistent supply of servo motors. Companies should evaluate their suppliers based on reliability, quality, and responsiveness. Establishing long-term partnerships can lead to better pricing, priority service during shortages, and improved communication regarding potential delays.

### 4. Stay Ahead of Technological Changes

To mitigate the risks associated with technological advancements, companies should invest in research and development to stay informed about emerging trends and innovations in servo motor technology. Regularly reviewing product lines and phasing out obsolete models can help minimize excess inventory and keep the inventory relevant.

### 5. Implement Cost Control Measures

Effective cost management requires a comprehensive approach. Companies should regularly review their purchasing practices, negotiate favorable terms with suppliers, and explore bulk purchasing opportunities to reduce costs. Additionally, adopting just-in-time (JIT) inventory practices can help minimize carrying costs by receiving goods only as needed.

### 6. Utilize Efficient Storage Solutions

Investing in efficient storage solutions, such as modular shelving or automated inventory management systems, can help optimize storage space and improve accessibility. Implementing a systematic organization strategy, such as categorizing motors by type or application, can also enhance inventory tracking and reduce the time spent searching for items.

### 7. Leverage Modern Inventory Management Software

Investing in modern inventory management software can significantly improve data management capabilities. These systems provide real-time insights into inventory levels, order statuses, and supplier performance. By automating inventory tracking and reporting, companies can make informed decisions, streamline operations, and reduce the risk of stockouts or overstock situations.

## Conclusion

Managing servo motor inventory, particularly for brushless motors, presents a unique set of challenges that require careful consideration and strategic planning. By understanding the intricacies of demand forecasting, supplier relationships, technological advancements, and effective inventory management practices, companies can navigate these challenges successfully.

Implementing advanced analytics, optimizing inventory diversification, strengthening supplier relationships, and leveraging technology are all essential steps in overcoming inventory challenges. As the demand for servo motors continues to rise across various industries, effective inventory management will play a crucial role in ensuring operational efficiency and maintaining a competitive edge.

In conclusion, while challenges in servo motor inventory management are inevitable, they can be effectively addressed through strategic approaches and the adoption of modern technologies. This proactive stance not only ensures that companies remain well-stocked with the right products but also enhances overall operational efficiency and customer satisfaction.